EWA Advanced Diploma

In October of 2024, the Edinburgh Whiskey Academy invited us to a pilot of their Advanced Diploma class. It built upon their Diploma in Single Malt Whisky and was a week long exploration of the craft. This was a residential class and our home for the week was the Dallas Dhu House, a 19th century manor house in Forres. Each day we had lectures and outings. We got to see things and explore locations that are not open to the general public. Our hosts were Vic Cameron, Kirsty McKerrow, Heather Smith, and Ian McKerrow. Vic was our primary instructor and the others stepped in wherever needed to provide support and logistics.

Day 1 - Malting

The first day of the advanced Scotch class presented a comprehensive overview of cereal grains and their integral role in whiskey production, under the guidance of Vic Camron. Participants explored the methods barley buyers use for evaluating grain, including sensory analysis and scientific metrics tailored for various malt types. The curriculum delved into the distinctions in malt treatment processes, such as steeping, germination, kilning, and mashing, emphasizing the specific qualities sought in barley for different whisky varieties. Notably, barley designated for grain whisky is selected for its enzyme content, while malt whisky barley prioritizes starch levels.

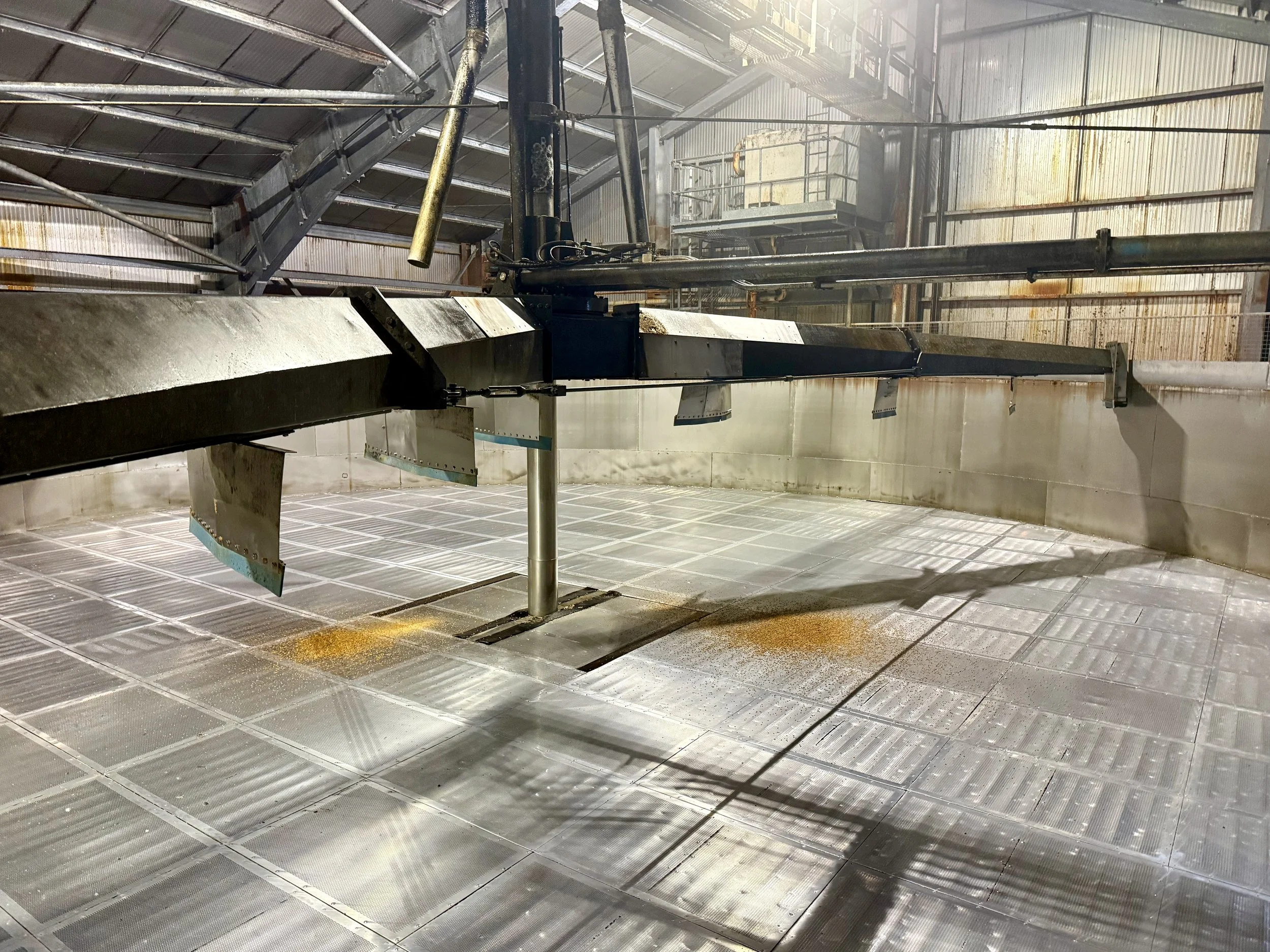

Discussions extended to the grain supply chain and the essentials of contract management, pinpointing factors that contribute to quality assurance, fair pricing, and sustainability within the industry. The day progressed with a visit to Crisp maltings in Portgordon, where attendees experienced the operations of a large-scale malting site producing both peated and unpeated malt. The facility tour provided insights into the complete malting process, from the intake of barley to the drying and kilning stages, alongside an examination of the lab where barley undergoes testing before acceptance.

Andy Ballantyne, our knowledgeable guide, was instrumental in addressing a myriad of questions, enriching the learning experience. The day concluded with a traditional dinner featuring Haggis, Tatties, and Neeps at Dallas Dhu house. Participants had the opportunity to sample an array of new-make spirits, each distinguished by unique ingredients, including varied yeasts and grains such as rice. This enriching first day laid a solid foundation for understanding the complexities of whisky production and its underlying components.

Day 2 - Mashing & Fermentation

On day 2 we began where we had left off the day before to discuss milling and mashing.

For milling, most Scottish distilleries use roller mills and recent innovations add grist analysis to optimize efficiency. There are some hammer mills, but production centers mostly on softer grains that don’t require the violence of a hammer mill. The exception would be for distilleries that use mash filter systems (there are two in Scotland).

We also talked about the various lautering systems and their tradeoffs.

We talked a lot about yeast metabolism and some of the lesser known requirements and byproducts. For example, this year’s barley harvest is coming in with very low Nitrogen numbers - perhaps too low to provide the amino acids that yeast needs to replicate so there is a bit of a fear that yields for the year may be down. We also talked a bit more in-depth about the role of Sulphur and byproducts containing it.

After lunch we took a tour of the Glenburgie distillery. Like the maltings yesterday, this distillery doesn’t have a visitor’s center and is not generally open for tours. Glenburgie is one of the components of Ballantines. The tour featured a tasting where we tried a Ballantines Glenburgie Single Malt 15 yr. A Balletine’s 17 year, and a Ballentine’s 30 year. The Glenburgie single malt shined in the blends.

Then we got a special treat. Our guides, Andrew and Sam, took us in the basement of the old custom’s house on-site and let us try a Ballantines from a cask filled in 1976 - so a 48 year old. It was sublime with orchard fruit and honey and a good back-end of barrel spice and tannin. Quite special and very nice.

We left Glenburgie and took a trip to the Benromach distillery and visited their tasting room. We enjoyed a flight of whiskies that included the country’s first organic whisky, a comparison of barrels with air-dried staves vs kiln dried, and a highly peated Benromach.

Before dinner we took a scenic drive over the moors and stopped to have a Tamdhu on the bank of the Spey river under the Craigellachie bridge. Then we visited the Craigellachie petrol station which is a little known, but well stocked whiskey shop.

Dinner was at the Spey Inn at the Craigellachie hotel. And afterward we visited the bar upstairs. I met Parker (full name Peter Parker but he’s cool enough to be known by his last name), the bar manager, who happens to be a Daschund.

Day 3 - Distilltion

Day three focused on distillation. Our teacher, Dr. Gordon Steele, started with the basics: a mix of ethanol, water, and congeners boils at a specific temperature based on their concentrations. We examined a chart that illustrated the link between alcohol concentration in an ethanol/water mix and its boiling point, similar to a whisky still. This explained how distillation concentrates alcohol and congeners, showing how it works and how the graph can help predict still performance. We also discussed how adding more heat changes the results. Finally, we explored the role of reflux and how the shape of the still impacts it.

Dr. Steele explained how to build a grain still, also called a column still. We connected this to how the plates in a column still relate to the pot still we just learned about. The graph indicated that a column still should ideally have 4 plates, but modern grain stills often have 30 or more. We then discussed why that is, using changes in how we read the graph for insights.

We explored different types of column still systems. A typical grain still in Scotland today has 5 columns, and we discovered the reasons behind this.

We explored different types of column still systems. A typical grain still in Scotland today has 5 columns, and we discovered the reasons behind this.

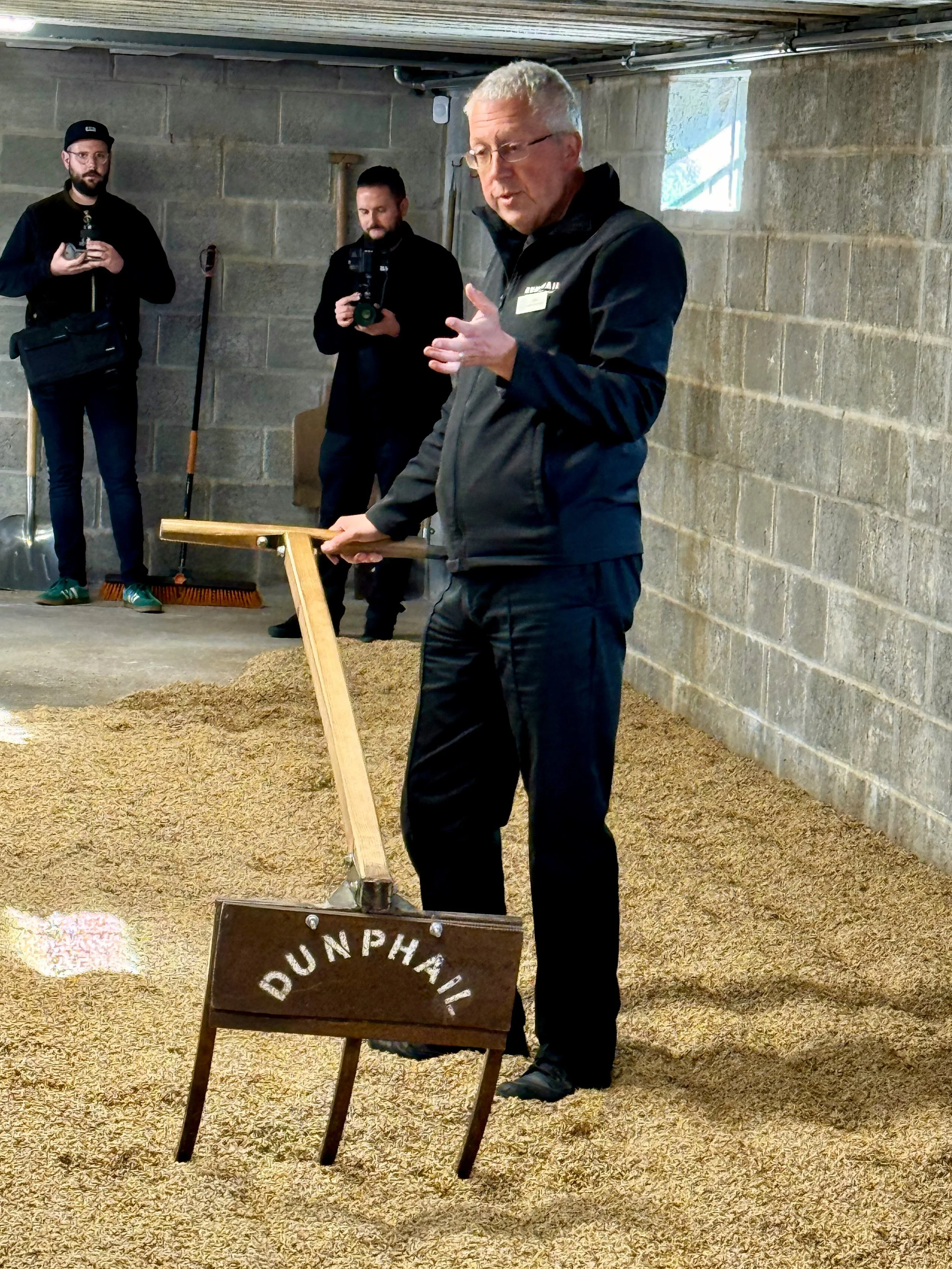

After lunch, we visited the Dunphail distillery, a new distillery in Speyside that produced its first barrel in October 2023. It's mostly off-grid, using solar panels and battery storage for most of its electricity, with additional energy from CNG. They have the first new maltings built in about 125 years. They use a two-step steeping process, spreading 3.5 tons of grain on the floor to germinate for 5 days, turning it 7 times daily. The malt is dried over peat or anthracite coal based on need, using an electrically heated fan powered by solar energy.,

They process 1 ton of the malt at a time using a 4-roller mill, then move it to a mash tun. The mash goes into large wooden fermenters where it ferments for a long 168 hours with a special yeast. Their aim is to imbue their spirit with fruity flavors. They use two wash stills and one spirit still. We tasted their new spirit in the warehouse; it was spicy, complex, and a bit sour. They are using various sherry casks and plan to release their first bottles in four years.

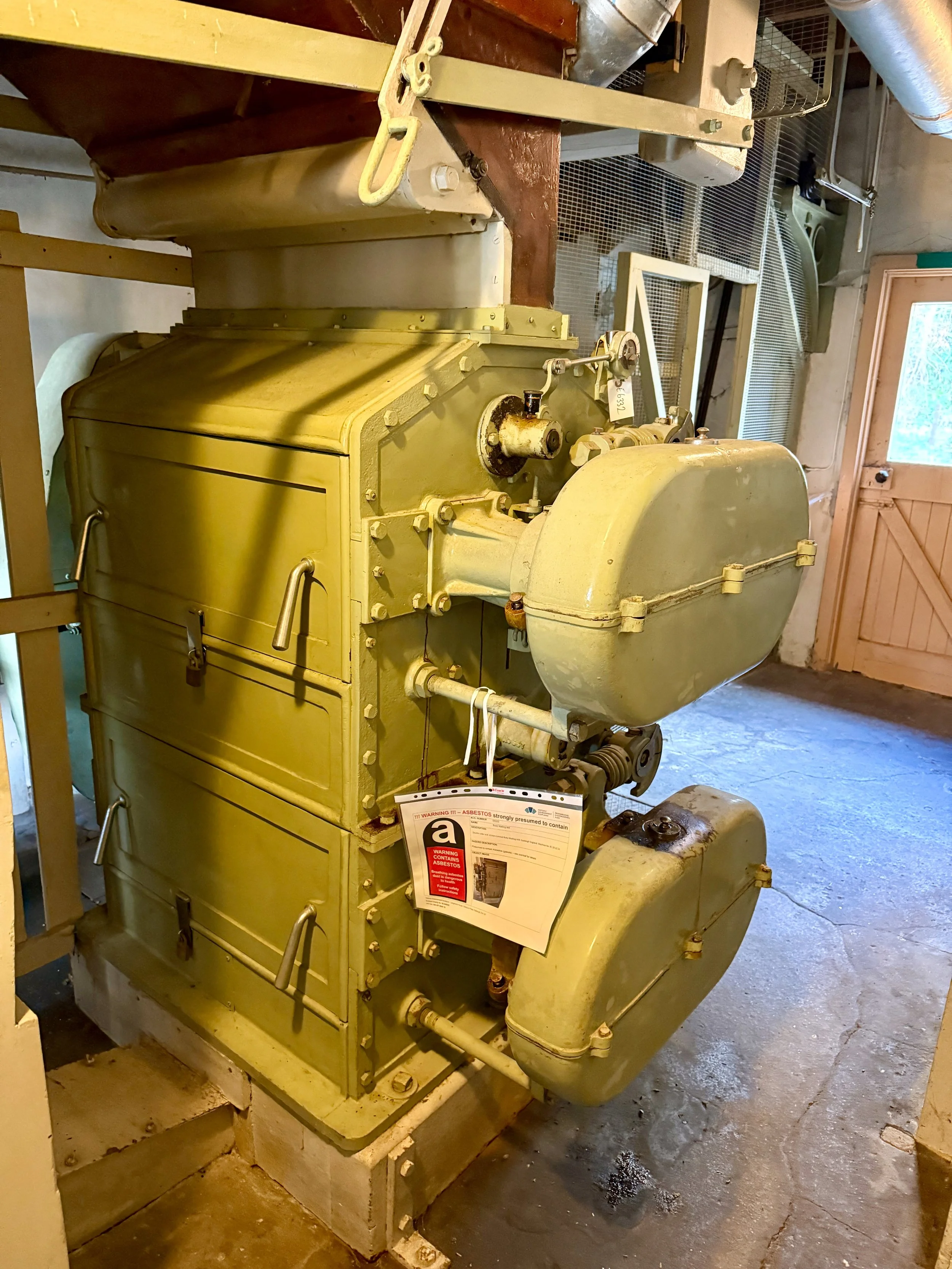

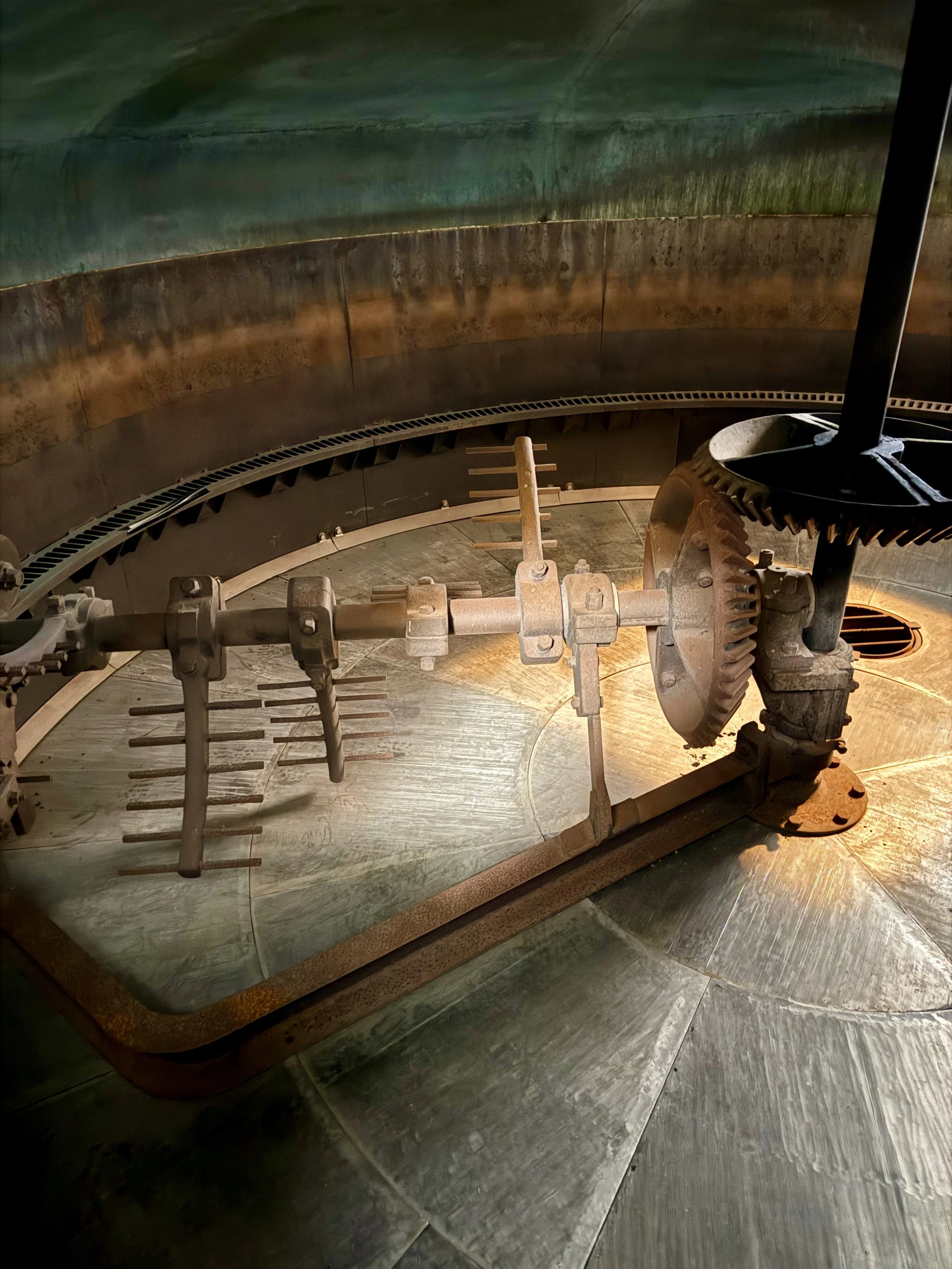

We visited the Dallas Dhu distillery, which closed in 1983 and became a museum in 1993 until COVID-19 forced it to shut down. A private company now owns it and plans to reopen in a few years. We explored the distillery and its old equipment. When it closed, everything was left as it was, even the distillery manager’s office with unused paperwork. It was fascinating, a bit sad, and slightly eerie.

We went back to the house and before dinner, we tried samples from a local distillery showing how new whiskey is made. We smelled the different stages: foreshots, hearts, and tails. Then, we mixed the hearts samples and compared the new whiskey to the finished product. It was a fantastic way to see the process from the morning!`

Day 4 - Maturation

On our outing to the Speyside cooperage, we ran into fellow whisky Somm Jasper Lyons, who had just finished his Diploma in Single Malt Whisky. He joined us for the tour and lecture. We saw craftsmen repairing casks right in front of us. Most of their work is repairing, but they also make some casks. Most new casks come from the US, France, or Spain. Apprenticeships last four years, and graduates are guaranteed a job.

After the tour, we used the cooperage's coffee bar for a Zoom lecture with Professor Alan Wolstenhome. He taught us about oak wood and why it's favored in the industry. We discussed oak's growth patterns and how different species affect whisky's flavor. We also covered the role of casks and their impact on the business.

Afterward, we had lunch at a pub in Aberlour. Jennifer Hastings Thompson wanted to try a whisky from Daftmill, a small distillery producing under 6,000 bottles each season. She ordered a pricey pour that was outstanding—rich, intense, and a classic Speyside. If you can afford it, I highly recommend trying it! Luckily, I convinced her not to buy a bottle... for now.

After lunch, we visited a whisky shop and bumped into Jasper again. It was right across from the original Joseph Walker bakery, known for its shortbread. Jennifer bought an expensive whisky, and I picked up a box of cookies. We then went to the Coleburn distillery, which has been closed since the 1980s, but the warehouses are still used by Aceo and the Murray McDavid independent bottler. They lease space to others. Inside, we saw some impressive casks aged 20, 30, and even 50 years, all well cared for. I can't share specific details since we were asked not to, and I even blurred the labels in our photos. Finally, we returned home for a delicious dinner of roast lamb, leeks, cabbage, and potatoes.

Day 5 - Test Day!

We slept in and had a late breakfast.

Our main activity was a review session where we could ask questions.

The test was divided in two parts. The first part of the assessment focused on sensory skills. We tasted a whisky and had to describe it both with and without water, guessing the distillery and age as best we could.

Everyone did well, identifying a whisky aged in ex-bourbon barrels and finished in sherry barrels. Vic, however, had throw in a twist as this was actually a grain whisky featuring wheat. Some of the students had noticed it seemed unusual, but nobody got it exactly. Still we did very well overall.

The second part of the test was an essay with 12 questions, three from each section. Luckily, we only had to answer 6 questions, one from each section. It took three hours to complete.

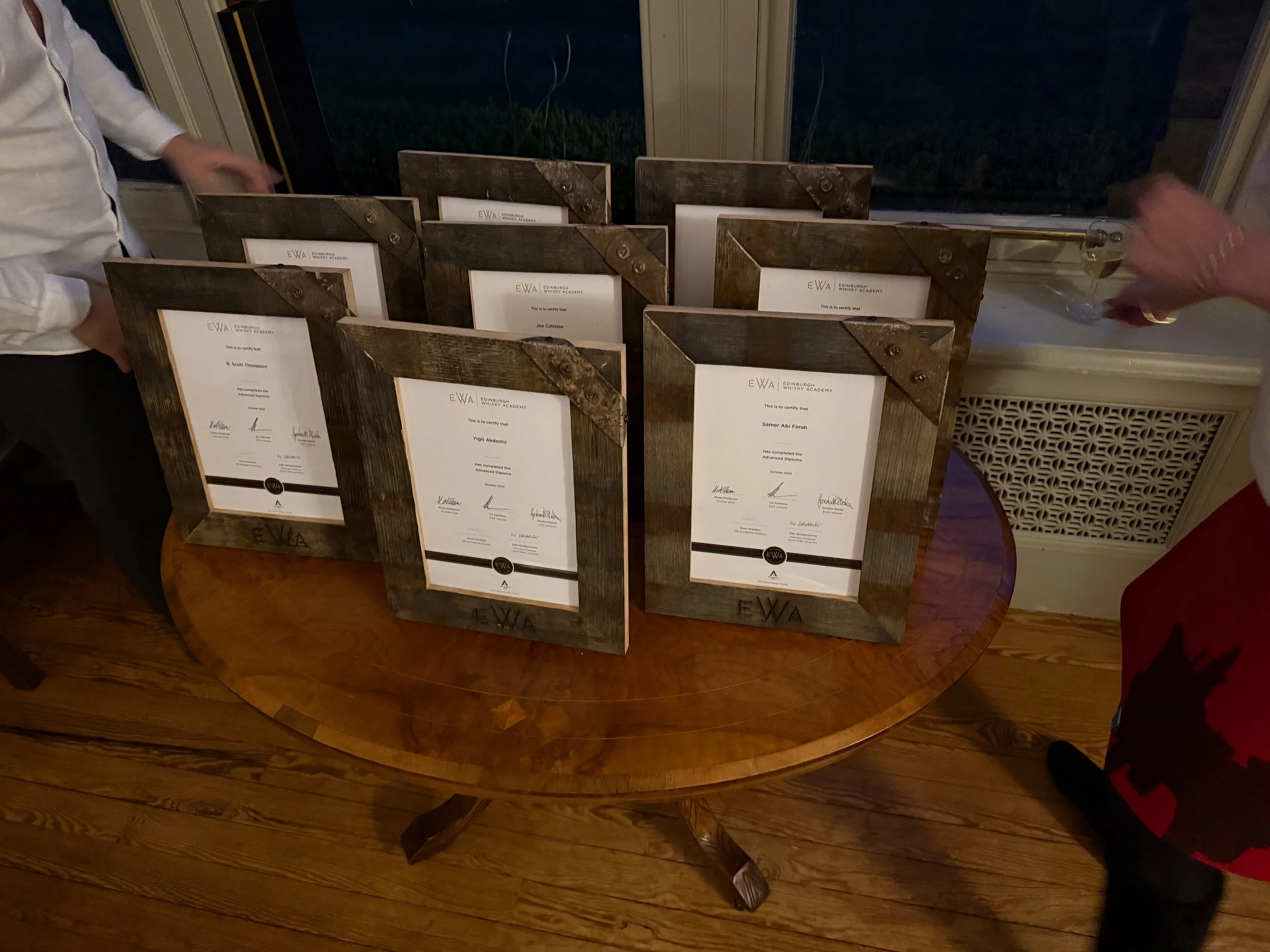

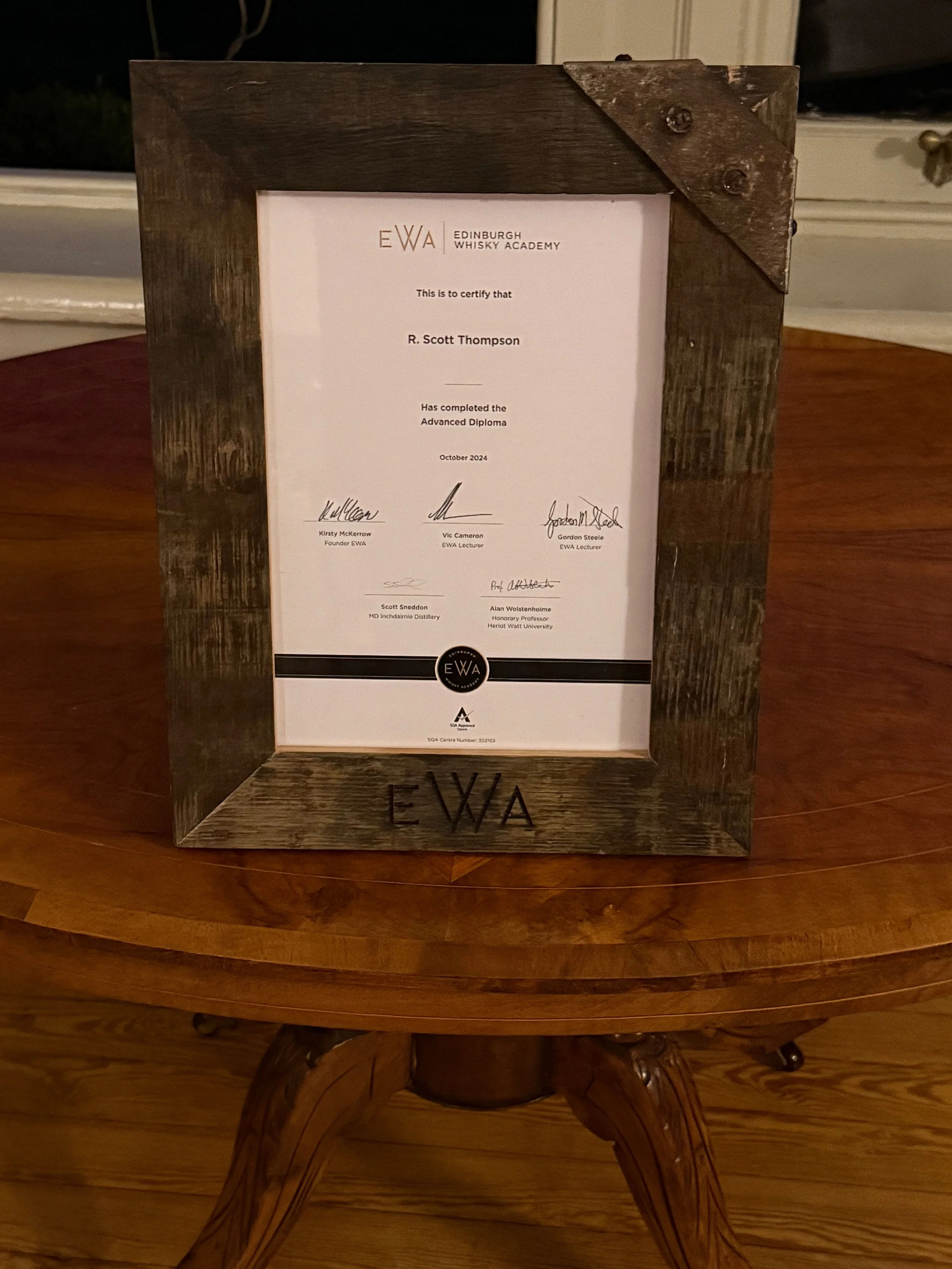

In the end, everyone succeeded, and we played Snooker afterward. At 7:00, we had an awards ceremony with a piper and a fancy dinner. Jennifer is the only woman in the world with this diploma since it was a pilot class. Together, we make up 25% of those with the Advanced Diploma. After the awards, we had a great dinner with new friends and enjoyed some drinks—though I can't remember how many!

It was an amazing week, but the only downside was our car arriving at 5 am to take us to the long plane flight home

The Advanced Diploma class was an unforgettable experience! We learned a lot from amazing instructors and gained equally, if not more, valuable insights from the industry experts we got to talk with - the people who create Scotch whisky for a thirsty world.

EWA is a top-notch program that offers excellent courses. Copper Widow provides EWA courses in Scotch and Irish whisky, gin, and whisky sensory. If you’re interested in taking one of our courses, let us know!